Createc are a company of researchers and entrepreneurs developing new applications of imaging technology, often helping clients see the bigger picture. One of their reasons for being is to create and improve the technology used for nuclear decommissioning.

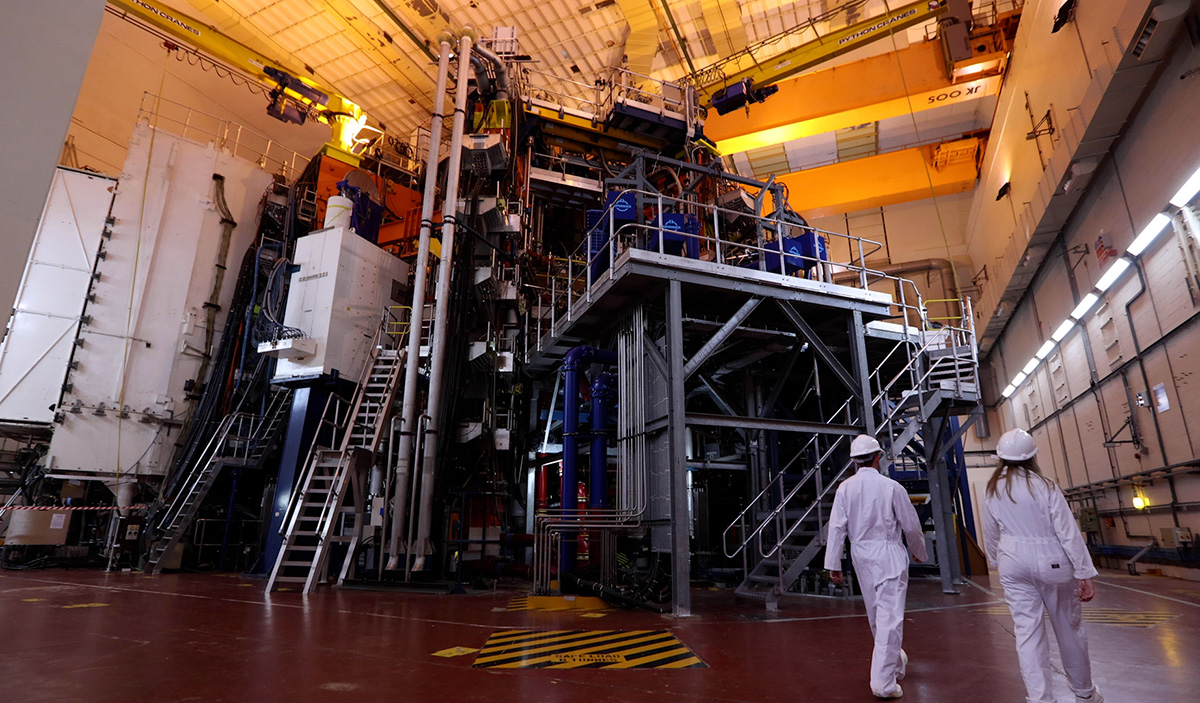

One of the big challenges with nuclear power is how to safely decommission a radioactive or hazardous site without posing a risk to human health. Createc used their project ‘Elephants to Ants’ (E2A) to trial a method for using a team of specialised robots to perform an end-to-end inactive decommissioning demonstration. We were lucky enough to be commissioned to film the demo week at UK Atomic Energy Authority’s RACE facility at Culham Science Centre.

The underlying principle of E2A is the integration of multiple relatively small robots or devices (‘ants’) working together to achieve goals beyond their individual capabilities, eliminating the need for a large, complex, ‘one size fits all’ machine (likened to an ‘elephant’). The Elephants to Ants vision is of a modular robotics decommissioning system in which a toolkit of robotics modules can be controlled through a single interface and reconfigured to solve many decommissioning challenges. Just like you can use a mouse and keyboard to do any task on a computer, the demo simply used a VR headset and two hand controllers to complete each operation.

This project required a project summary video for the government and investor partners, showing the five steps that were demonstrated. We also made five smaller ‘chapter’ films from the same material so that the process could be explained in smaller chunks if necessary.

The film was underpinned by a key interview with Createc’s Managing Director Matt Mellor, who knew the topics to cover inside out. By getting him to run through the topics in varying degrees of simplicity and speed, we were able to get enough choices for our edit that would bring in the film under the requested ten-minute run time. This was no mean feat as there was a great deal to cover, but we encouraged everyday language and answers that would make the topics easily understandable.

The rest of the film was more like a documentary shoot where we needed to capture a good deal of the process on the factory floor and control room without getting in anyone’s way. We also utilised time-lapses from cameras in fixed vantage points for long processes and used screen recordings to capture the infra-red and VR views that the operator was seeing. The result was a very accessible project summary film that we and the client were both very proud of.